|

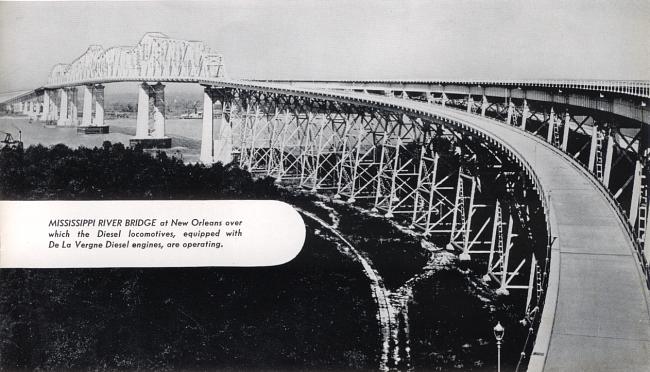

truck from the locomotive. Furthermore, if a trac- tion motor becomes jammed and will not rotate, the gear can be taken out of mesh with the pin- ion by moving the axle back in the pedestal ways, thus permitting the locomotive to be moved. The main locomotive frame is a substantial one-piece steel casting, which incorporates the fuel tanks, battery compartments, sand boxes, air duct for cooling the traction motors, and draft gear pockets. The fuel oil capacity (725 gallons) is large, permitting the locomotives to remain in service for considerable periods without refueling. Power is supplied by a De La Vergne, Model VO Diesel engine, which delivers 900-brake horse- power at 600 rpm. This is an 8-cylinder, 4-cycle, Diesel, 12 1/2-in. bore, 15 1/2-in. stroke. The engine has an idling speed of 300 rpm and several in- termediary speed settings which are controlled through an electro pneumatic governor operator in connection with the Woodward Hydraulic Governor The engines for these locomotives contain a number of unique features which should be of definite advantage, particularly in railroad work. An exclusive De La Vergne feature is the pat- ented combustion chamber which is of spherical shape and cast integral with the cylinder head and connected to the cylinder by a throat. The |

contour of chamber and throat are such that air rushing from the cylinder during compression stroke creates a controlled turbulence which as- sures thorough mixture of air and fuel, thus guar- anteeing freedom from smoke. Due to the turbu- lence, the air is carried to the fuel spray which permits a slow injection at low fuel injection pres- sure and, in turn, results in low firing pressures. The orifice sizes of the fuel injector are larger than usually found on Diesel engines and experience has shown that these spray nozzle holes do not clog up over long periods of time and the ex- cellent water cooling provided for these spray nozzels assures permanency of proper function- ing. In accomplishing mixtire of the air and fuel in a water cooled turbulence chamber located in the cylinder head, piston rings, cylinder liners, and valves are subject to considerable less heat. Resulting low temperatures of these parts elimi- nate ring sticking and frequent valve grinding periods. The engine drives a Westinghouse Type 486-B-2 Generator, which is of the single-bearing type, closely coupled to the engine by means of a mis- alignment coupling. The power plant throughout is of rugged construction and is conservatively rated. Engine and generator are mounted on a structural welded bed-plate, which insures proper alignment of all parts under any operating con- ditions to which the locomotive may be subjected. A composition pad is placed between the engine |

|